|

|

|||||||||||||||||||||||

|

|

|||||||||||||||||||||||

|

|||||

|

|||||

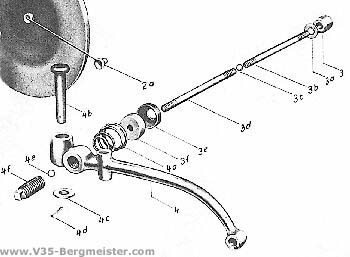

Clutch: |

|

|

||||||||||||

|

|

|||||

|

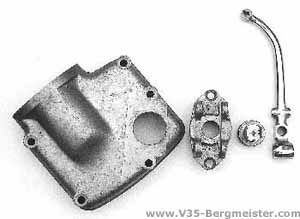

On the left the gearbox cover with the casted seat bearing for the clutch lever, used up to an engine no. of 3497. |

||||||

|

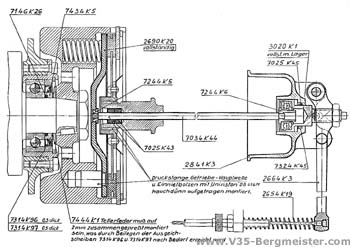

Since engine no. 3498 the clutch mechanism was completely redesigned (see picture right above and cross section below on the left). |

||||||

|

||||||

|

Cross section drawing taken from the Technical Bulletin No. 14 from July 1954) |

||||||