|

|

|

|

|

Frame: |

|

|

|

For the direct comparison of the frames we made use of two frames that are extremely different from their year of production. The old one has the number 35/152 (the 35 stands for V35 and has nothing to do with the frame number itself, it begins after the dash).

|

|

|

|

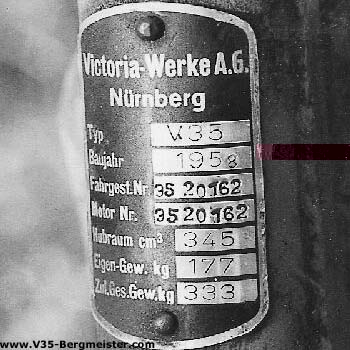

The new frame is a very special one (see picture of the number plate left hand). The production of the V35 stopped in 1956 as reported officially. This frame however is stamped with the year 1958 in its genuine number plate, showing a number of 20162. This number drops out of the continuously growing frame numbers of the serial prodiction, they must have reached no. 5000 at the end. A possible explanation might be the following: The plant maybe built up V35 Bergmeisters from the large stock of spare parts when the official production was already stopped, and they did this using a different frame numbering.

The highest recognized frame number is 35/5025, this frame is owned by our IG-colleague Anton Grabinger. If anybody owns a frame with a higher number, please contact us via email !

|

|

|

|

|

Type plate from 1958 with number that drops out of the serial numbering scheme.

|

|

|

|

The frame had a „predetermined breaking point“ in the area between the footrest lug and the center stand weldings (see arrow in the picture left), on the left and also on the right hand side. It is important to keep an eye on this area while restoring a Bergmeister.

The frame will not break down immediately with a hairline crack in this area, but it is better to recover this before painting, reassebling and riding.

This area was reinforced on later models (see picture below). There was a funny thing, the gap between the reinforcement plate and the center stand welding.

As many motorcycle oldtimers make more kilometers on trailers than on their own wheels, one should pay attention that the Bergmeister will be transported with stand up, resting on its two wheels onto a trailer. Otherwise stresses of road jolts may be carried through the stand in this sensible area and cause a frame failure there.

|

|

|

|

|

|

|

|

Other changes are recorded to the sheet metal carrying the rubber block of the riders seat. Early models have a continously welded bead to the frame tubes, this can be seen on the above picture. Later models (see picture below) have an interrupted welding with app. 6 cm long weldings, this measure had certainly no influence on stability.

There is another change in this sheet metal, usually there was a small dimple with a hole for the socket of the electrical sidecar connector located on the right hand side.

The later frames also had this dimple - without a drilled hole in it - on the opposite, left hand side. This must have been an option for left hand traffic and thus for using a left hand side car.

|

|

|

|

|

The frame was very stable with its reinforcements and designed for sidecar usage from the beginning. The potential sidecar user did not have to make use of any tube clamping devices, as he owns an exclusive motorcycle like the Bergmeister, there were threaded bells welded to the frame at useful locations (see above picture). They were covered with decorative aluminium bolts when not in use.

The later frames had these bells also on the left hand side. A thread is no more found in them, but there was now a hole drilled through from side to side to create a through-bolt fixing of the sidecar.

Let’s have a glance at the export situation of the Bergmeister. The through-bolt fixing offers again the option of a left-hand-mounting of the sidecar. Countries with left-hand-drive, and only there the left-hand sidecar makes sense, however have never imported the Bergmeister in large quantities.

In Europe we have to mention Great Britain and Sweden (till 1967) here, but a large variety of own motorcycle brands and the character of the British were obstacles to a Bergmeister success in Great Britain, in our worldwide register of Bergmeisters we only have one single bike there: It stands in the museum of the former trial champion Sammy Miller in Bashley Manor, where other “continental rarities” can be seen. In Sweden there are also only a few V35 known. In the U.S. we know of app. 50 Bergmeisters, 20 of their owners joined our registration.

|

|

|

|